- Home

- /

- Blog

Blog

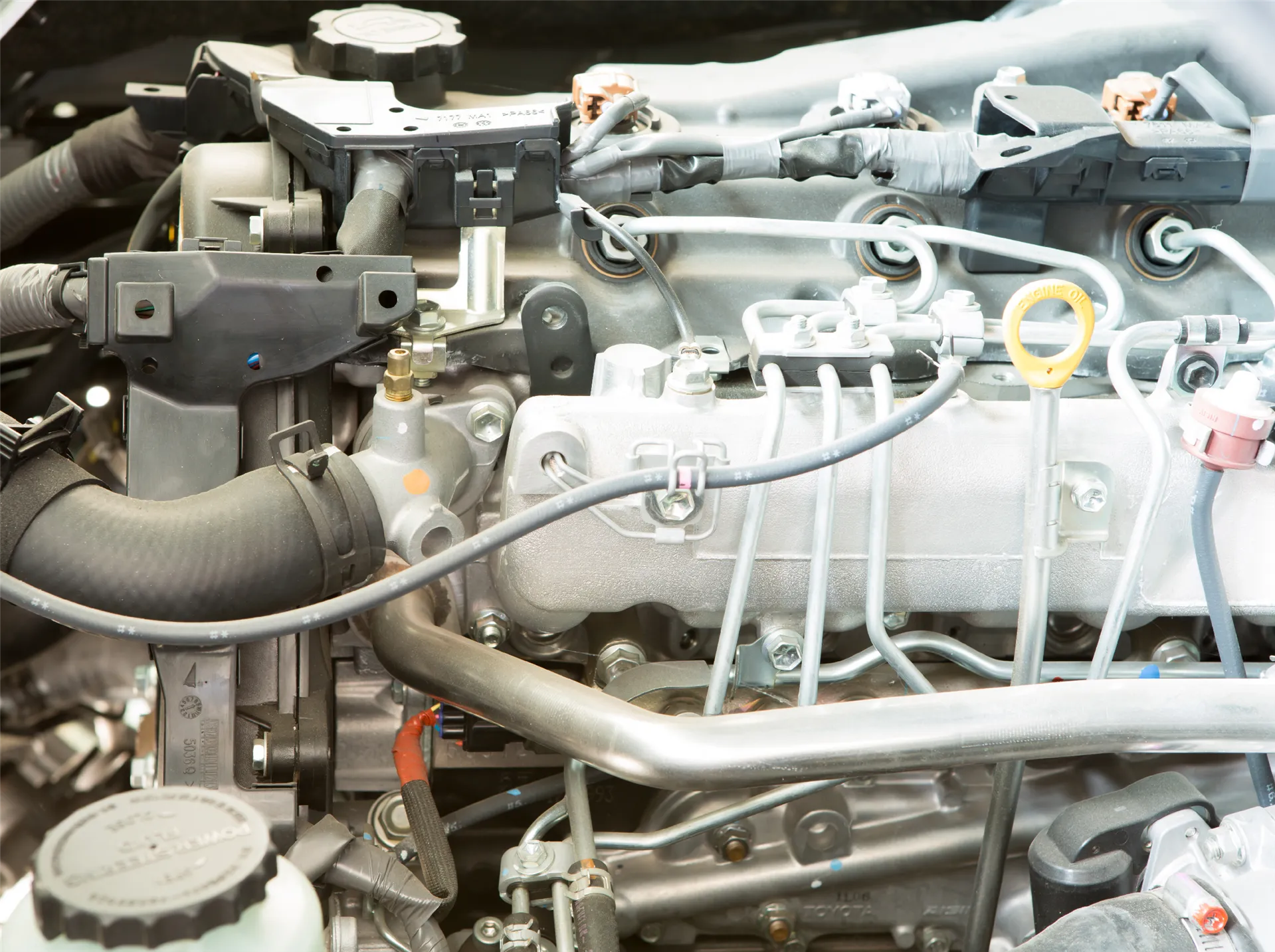

Achieving Efficient Performance in Engine and Compressor Systems

The Importance of Engine Oil and Filters

Engine oil and filters are critical for vehicle performance and longevity. Using the appropriate engine oil and regularly replacing filters reduces friction, enhances engine efficiency, and prevents wear. ARBE’s high-quality hoses and pipes maintain proper fluid flow and pressure balance in engine systems, supporting overall system performance.

- Change engine oil regularly according to manufacturer recommendations.

- Periodically inspect and clean or replace air, oil, and fuel filters.

- Using high-quality oil and filters increases engine efficiency.

- Ensure hoses and pipes are leak-free and functioning safely.

Why Compressor Pressure Drops and How to Solve It

A drop in compressor pressure directly affects system performance and can have several causes. Leaks in hose or pipe connections, worn valves, or insufficient lubrication may lead to pressure loss. ARBE’s high-quality hoses and pipes prevent leaks and ensure efficient operation of compressor systems.

- Regularly inspect compressor hoses and pipes and fix any leaks.

- Periodically check valves and seals for wear.

- Monitor lubrication levels to prevent friction and pressure loss.

- Using OEM-quality hoses and pipes enhances system performance.

Advantages of Detecting Failures Early

Early detection of failures in engine and compressor systems is critical for preventing serious damage and reducing maintenance costs. Unusual noises, pressure drops, or performance losses are early warning signs. ARBE’s quality-focused hoses and pipes ensure safe and smooth operation, minimizing the impact of such issues.

- Inspect the system if you notice abnormal noises or vibrations.

- Monitor pressure drops and performance reductions.

- Early intervention prevents issues from escalating.

- High-quality hoses and pipes enhance system safety and efficiency.